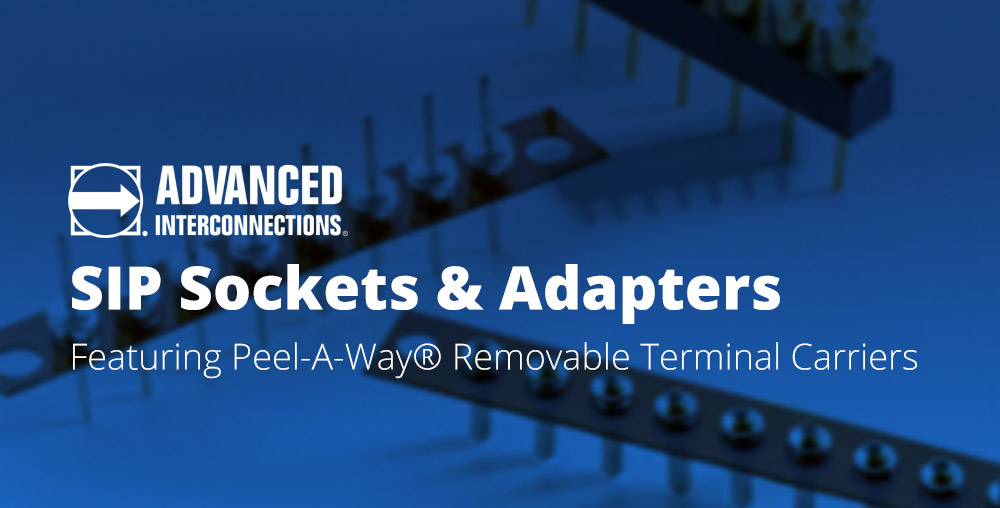

Advanced Interconnections’ high quality, dependable Single In-line Package (SIP) Sockets, Adapters, and Headers are designed with robust screw-machined terminals for superior performance.

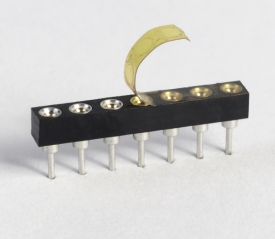

SIP Sockets and Adapters from Advanced are easily customized with a variety of insulator options, including Peel-A-Way® Removable Terminal Carriers, molded Solid Strips, and molded Snap Strips. The Snap Strips are breakable at .100/(2.54mm) increments to ensure you always have the right size strip on-hand. All models feature our screw-machined terminals with multi-finger contacts for proven reliability and performance.

Replace

Features

- Automated assembly compliant

- Tapered entry for ease of insertion

- Wide range of patterns and terminal styles, from 2 to 100 positions

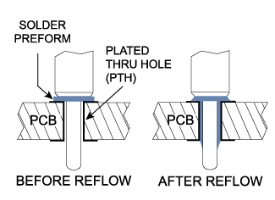

- Solder Preform terminals available for mixed SMT and thru-hole process applications

- Closed bottom sleeve for 100% anti-wicking of solder

- Optional Tape Seal on terminals protects contacts from contamination during board processing

- RoHS compliant insulators and terminals are compatible with lead-free processing – select either Matte Tin or Gold plating

Options

Peel-A-Way® Removable Terminal Carriers

Typical Applications: Eliminate hand-loading of pins, facilitate solder joint visibility, low profile component mounting or board mating

- Place socket on PC board

- Send PC board and socket through soldering operation

- Peel away polyimide film carrier for complete solder joint visibility or leave in place for added stability

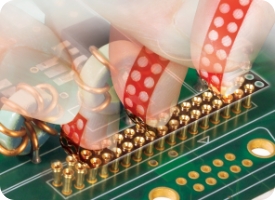

Snap Strips

Typical Applications: R&D labs, testing, repair, job shops, distributors; anywhere a variety of SIP socket or adapter sizes (pin counts) are needed.

- Simplify inventory by keeping strips on hand and easily “snapping” to the exact size needed

- Available with a wide variety of socket terminals or adapter pins

- Breakable at .100/(2.54mm) increments

- Available in 20, 30, or 32 positions

Solder Preform Terminals

Typical Applications: Intrusive reflow, eliminate need for wave soldering on mixed SMT/Through-hole boards

- Combines the labor of socket loading and solder application into one operation

- Eliminates use of solder paste and the screening operation

- Eliminates solder bridges and/or solder shorts due to excess solder

- Ensures a reliable solder joint with controlled solder volume

- Ideal for surface mount and mixed technology applications

Tape Seal

Typical Applications: Harsh environments, long term storage, applications that call for spray flux

- Removable tape seal protects plated contacts in harsh environments.

- Sealed socket will not allow contaminants to enter socket chamber and become entrapped behind contact fingers.

- Spray flux without contaminating contact area.

- Material: Silicone backed polyimide film, -74° C to 260° C (-100° F to 500° F), intermittent to 371° C (700° F).

More Info

_

HHP is honored to serve as a manufacturer’s rep for Advanced Interconnections, a leading designer and manufacturer of innovative, technologically advanced interconnect solutions.